Powder Coating Machines are indispensable assets in the world of surface finishing, enabling the creation of high-quality, durable coatings. As a leading industrial finisher put it, "A top-notch

Powder Coating Machine is the linchpin of our production process, delivering flawless finishes that meet the most stringent industry standards." Another astute business owner remarked, "Investing in a reliable

Powder Coating Machine has not only enhanced our product quality but also significantly boosted our operational efficiency."

A

Powder Coating Machine is a sophisticated assembly of components designed for precision coating. The powder coating gun, the heart of the machine, features an ergonomic handle for comfortable operation, a finely-tuned powder flow control valve that allows for precise adjustment of powder output, and a specialized nozzle for optimal powder atomization. In electrostatic powder coating machines, an advanced electrostatic charging system imparts a consistent electric charge to the powder particles, ensuring superior adhesion to the workpiece. The powder feeder, a crucial auxiliary component, stores and metes out powder to the gun at a steady, controlled rate. High-end machines often incorporate a powder reclaim system, which utilizes advanced filtration or cyclone technology to capture and recycle oversprayed powder, minimizing material waste and reducing operational costs.

The versatility of

Powder Coating Machines makes them a staple across diverse industries. In the automotive sector, these machines are employed to coat car bodies, engines, and various components, providing a resilient, corrosion-resistant finish that enhances both aesthetics and longevity. The furniture industry relies on

Powder Coating Machines to apply a protective and visually appealing layer to metal frames and parts, ensuring durability and resistance to wear and tear. In the electronics industry,

Powder Coating Machines are used to coat metal enclosures of electronic devices, safeguarding them against environmental factors and electromagnetic interference. Additionally, small-scale workshops and DIY enthusiasts leverage these machines to undertake custom coating projects on a wide range of metal items, from jewelry and home decorations to small automotive parts.

The cost of a

Powder Coating Machine is influenced by its features, performance capabilities, and build quality. Entry-level manual powder coating machines, suitable for occasional DIY use or small-scale projects with basic requirements, typically range from $100 to $500. These machines offer fundamental functionality and a straightforward powder feeding mechanism. Mid-range machines, equipped with electrostatic charging systems and improved build quality, are priced between $500 and $2000. They provide enhanced performance and greater control over the coating process. High-end professional-grade

Powder Coating Machines, boasting advanced features such as precise powder flow control, multiple spray patterns, and efficient powder reclaim systems, can exceed $2000. These machines are designed to meet the demanding needs of large-scale industrial production.

To ensure optimal performance and a high-quality coating, proper usage of the Powder Coating Machine is essential. Before commencing the coating process, meticulously assemble all components and ensure they are correctly grounded to prevent electrical hazards. Fill the powder feeder with the appropriate powder, taking care to avoid contamination. Adjust the powder flow rate and, if applicable, the electrostatic charge settings according to the specific requirements of the workpiece and the powder type. Maintain a consistent distance of approximately 15-20 cm between the powder coating gun and the workpiece, and move the gun in a smooth, even motion to achieve an even coating. After each use, thoroughly clean the powder coating gun and powder feeder to remove any residual powder, preventing clogs and ensuring consistent performance.

Selecting the right

Powder Coating Machine requires careful consideration of your specific needs and usage patterns. For high-volume industrial production, opt for a machine with advanced features, robust construction, and high productivity capabilities. If you are a beginner or plan to undertake occasional small-scale projects, a basic machine with essential functionality may suffice. Evaluate the type and complexity of the workpieces you will be coating; intricate shapes and detailed surfaces may require a machine with adjustable spray patterns and precise control. Additionally, consider the reputation of the manufacturer, the availability of spare parts, and the quality of after-sales support to ensure long-term reliability and optimal performance.

When operating a

Powder Coating Machine, safety should be a top priority. Wear appropriate personal protective equipment, including a dust mask, safety goggles, and gloves, to protect against powder inhalation, eye irritation, and skin contact. Ensure that the work area is well-ventilated to prevent the accumulation of powder particles, which can pose a health hazard. Keep the machine away from flammable materials and sources of ignition, as powder coatings can be combustible. Regularly inspect the machine for any signs of damage, wear, or malfunction, and promptly address any issues to prevent accidents and ensure safe operation.

The design of a

Powder Coating Machine is a testament to engineering ingenuity, combining functionality, efficiency, and precision. The electrostatic charging system in modern machines significantly improves powder adhesion, reducing powder waste and ensuring a uniform, high-quality finish. The adjustable powder flow rate and spray patterns offer unparalleled flexibility, allowing users to customize the coating process according to the specific requirements of each workpiece. The inclusion of a powder reclaim system in advanced machines not only minimizes material waste but also contributes to environmental sustainability and cost savings. Overall, the design of powder coating machines is optimized to deliver consistent, reliable performance and exceptional coating results.

Q: What steps should I take if the powder coating applied by the Powder Coating Machine is uneven?

A: First, carefully check and adjust the powder flow rate to ensure a consistent output. Verify that the gun is held at a consistent distance and angle from the workpiece throughout the spraying process. If using an electrostatic model, ensure that the electrostatic charge settings are correctly configured. Additionally, inspect the powder for any clumps or inconsistencies that may affect the coating quality.

Q: Is it possible to use different types of powder coatings with the same

Powder Coating Machine?

A: Yes, it is possible to use different types of powder coatings with the same machine. However, it is imperative to thoroughly clean the machine, including the powder feeder, gun, and any associated components, between different powder types to prevent contamination. Different powder coatings may have specific application requirements, such as temperature, curing time, and electrostatic charge settings, which should be carefully followed to ensure optimal results.

Q: How frequently should I perform maintenance on my Powder Coating Machine?

A: Regular maintenance is essential to ensure the optimal performance and longevity of your powder coating machine. Clean the powder coating gun and powder feeder after each use to remove any residual powder. Periodically inspect the machine for any signs of wear, damage, or malfunction, and lubricate moving parts as recommended by the manufacturer. Conduct a more comprehensive maintenance check, including checking electrical connections and calibrating the electrostatic charging system, at least once every few months or as specified in the user manual.

Q: What should I do if the powder fails to flow properly from the Powder Coating Machine?

A: Start by checking the powder feeder for any blockages or obstructions that may be impeding the flow of powder. Ensure that the powder is not compacted or moist, as this can affect its flowability. Verify that the powder flow control mechanism is functioning correctly and that the settings are appropriate for the powder type and workpiece. If the problem persists, inspect the powder hose and connections for any leaks or damage that may be causing a disruption in the powder flow.

Q: Can I upgrade the features of my existing Powder Coating Machine?

A: In some cases, it may be possible to upgrade the features of your powder coating machine. However, this depends on the design and compatibility of the machine. Some common upgrades include adding an electrostatic charging system, replacing the powder coating gun with a more advanced model, or installing a powder reclaim system. Before attempting any upgrades, it is advisable to consult the manufacturer or a qualified technician to ensure that the upgrades are feasible and will not void the warranty.

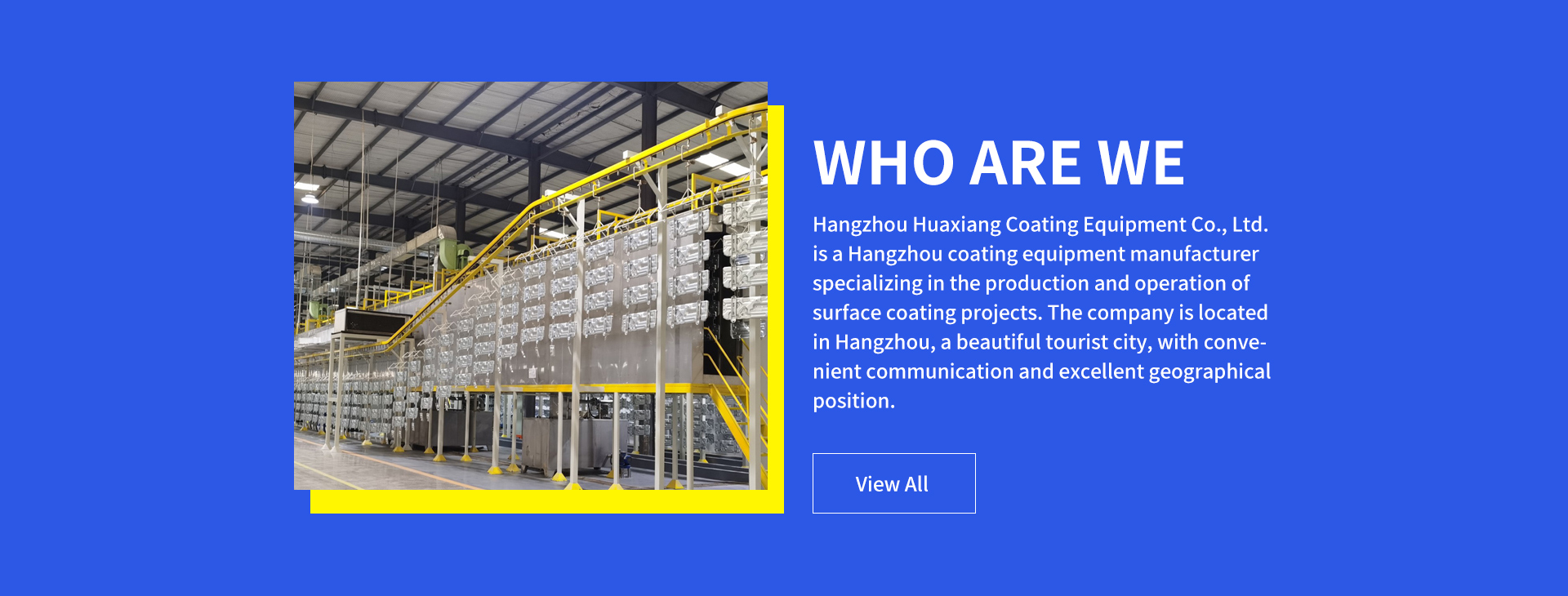

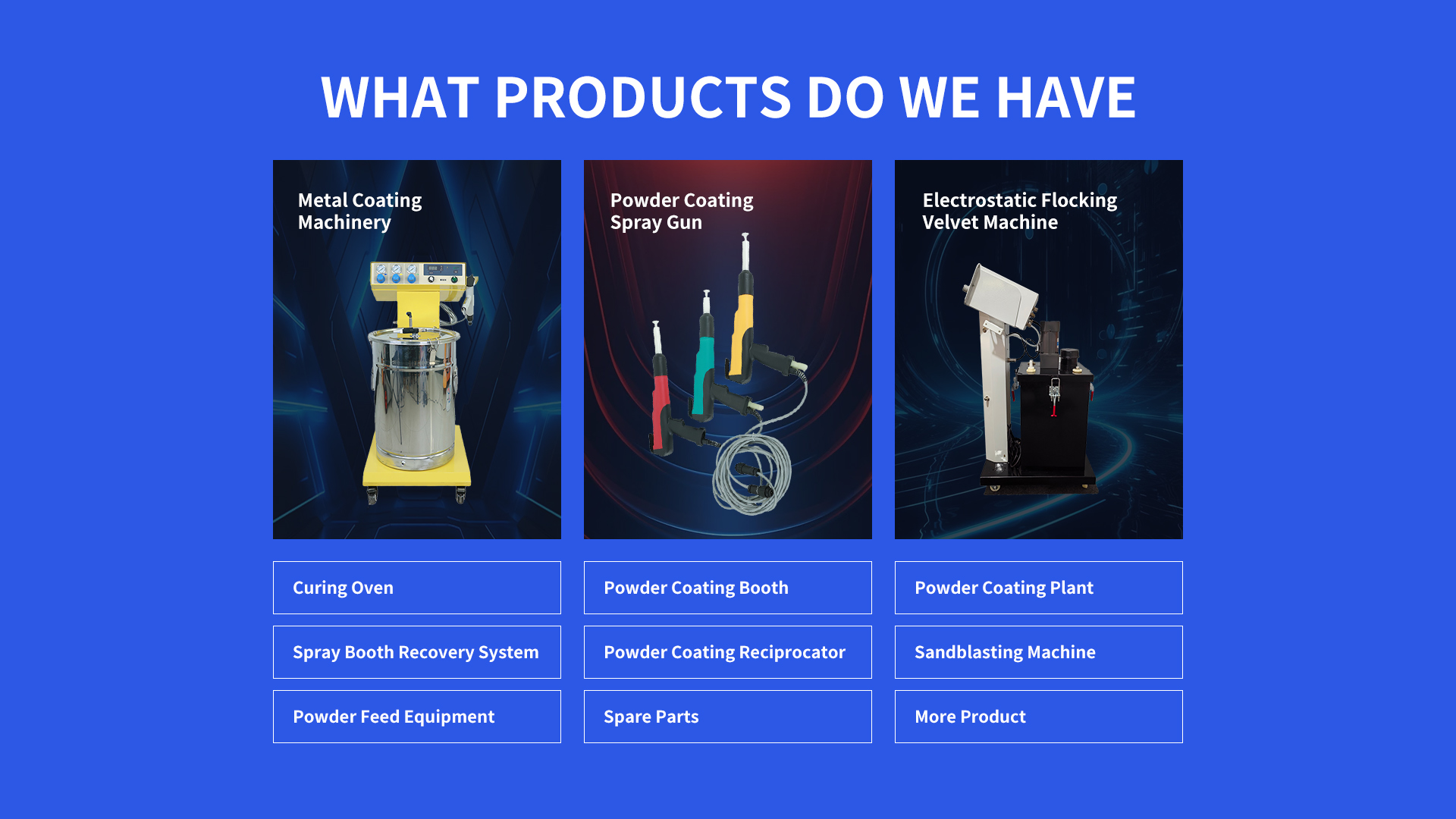

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com